As we undergo digital transformation, we must reconsider the value of physical assets. Instead of being viewed as static equipment, AI-enabled physical assets have the capability of being intelligent systems that can communicate their condition. The combination of digital sensors and artificial intelligence shifts operational strategies. AI-enabled IoT data is a game changer. It allows companies to process the raw data obtained from machinery into operational signals that can be leveraged along the entire life cycle of that asset to increase efficiencies.

More and more businesses are seeing the value of sophisticated IoT solutions and are seeking to implement them to capture, manage, and analyze data from their equipment, infrastructures, and other remote devices. This data, combined with AI, shifts business decision making from a reactive to a proactive and predictive level. This is the level of sophistication that is fundamentally driving change in the management of the life cycle of assets in an IoT environment. With this level of sophistication, businesses can effectively manage and minimize downtime, increase the useful life of their equipment, and reduce operational expenditures.

Redefining the Modern Asset Life Cycle

An asset’s life cycle consists of the entire process from planning and acquiring the asset, deploying, operating, optimizing, and, finally, retiring the asset. Traditionally, companies have given the most focus to the operational phase. However, opportunities to increase efficiencies in this phase are often missed in the early planning and late evaluating stages.

Integrating AI into asset management enables analysis and expansion at each step of the process. For example, AI can analyze multiple data streams and monitor performance, use, and deterioration trends of assets. Decision-makers can continuously monitor assets and dynamically change management strategies, which is more responsive than waiting for historical reports, routine maintenance, and reports.

AI replaces educated guesswork by using data intelligence. Instead of isolated inert units, assets are integrated as living and responsive data units.

AI-Enhanced IoT Ecosystems

Artificial intelligence (AI)-enhanced Internet of Things (IoT) ecosystems utilize a modular technological framework. While there are deviations in application from one industry to another, there are five common core components in most ecosystems:

- Integrated sensors

- Safe data transmission and connectivity

- Scalable processing through cloud or edge computing

- AI-based anomaly detection

- Decision-making dashboards

This framework enables ongoing process improvement through predictive analytics based on historical data.

Predictive Maintenance Through Artificial Intelligence and the Internet of Things

One of the main ways that AI integrated with the Internet of Things is useful is through predictive maintenance. No longer do companies have to wait for machinery to break and repair it afterwards, or service assets at fixed time intervals. It is now possible for companies to predict and anticipate what issues may arise and address them before they become bigger problems.

Predictive maintenance is the result of a combination of past documentation and real-time sensor data. Subtle changes such as vibration frequency changes, and changes of varying degrees in temperature, can be analyzed and predicted accurately by AI and therefore lead to anticipatory maintenance requests.

A predictive maintenance program can lead to increased workplace safety, increased safety in the workplace, optimized maintenance costs, longer lasting equipment, greater and more efficacious inventory as well as less unplanned stagnant equipment.

Predictive maintenance protects assets and preserves streams of revenues for the company by eliminating gross operational interruptions.

Predictive Analytics through Artificial Intelligence with the Internet of Things

The data generated by the Internet of Things devices is valuable to companies only in as much as it can be explained. This predictive analytics system using artificial intelligence is a method that allows companies to utilize data generated by a predictive maintenance system in a forward looking and strategic way. Artificial intelligence is able to analyze operational data and make reliability and operational efficiency predictions, identify and diagnose system operational issues and inefficiencies, predict system failures, and suggest operational strategies for system reconfiguration.

For optimizing production when production speed and equipment strain get to be well correlated, AI is capable of identifying the ideal operational strain of equipment. In predictive maintenance analytics, the artificial intelligence system can predict level imbalance of loads in the energetic system and recommend a reactive maintenance reconfiguration.

The effects go further than just maintenance. AI driven IoT data also aids in:

- Energy Optimization

- Benchmarking of asset performance

- Planning and forecasting of capacity

- Assessment of operational risks

- Modelling of life cycle costs

When organizations implement predictive analytics on IoT asset life cycle management, they go from reactive control to intelligent orchestration.

Real-World Impact: Industry Applications

The application of AI in asset management transforms industries, as the varying implementation approaches demonstrate.

In manufacturing, machines can provide ongoing insights into production performance. In the transportation industry, fleet managers can assess engine performance and optimize routes in real-time. In the utility industry, predictive analytics are used to optimize the flow of energy.

The benefits are the same in all industries:

- Operational Transparency

- Regulatory Compliance

- Environment Sustainability

- Competitive Advantage

- Asset Utilization

The standardization of AI-driven IoT methods, and replacement of experimental innovations, is evidenced through the benefits listed above.

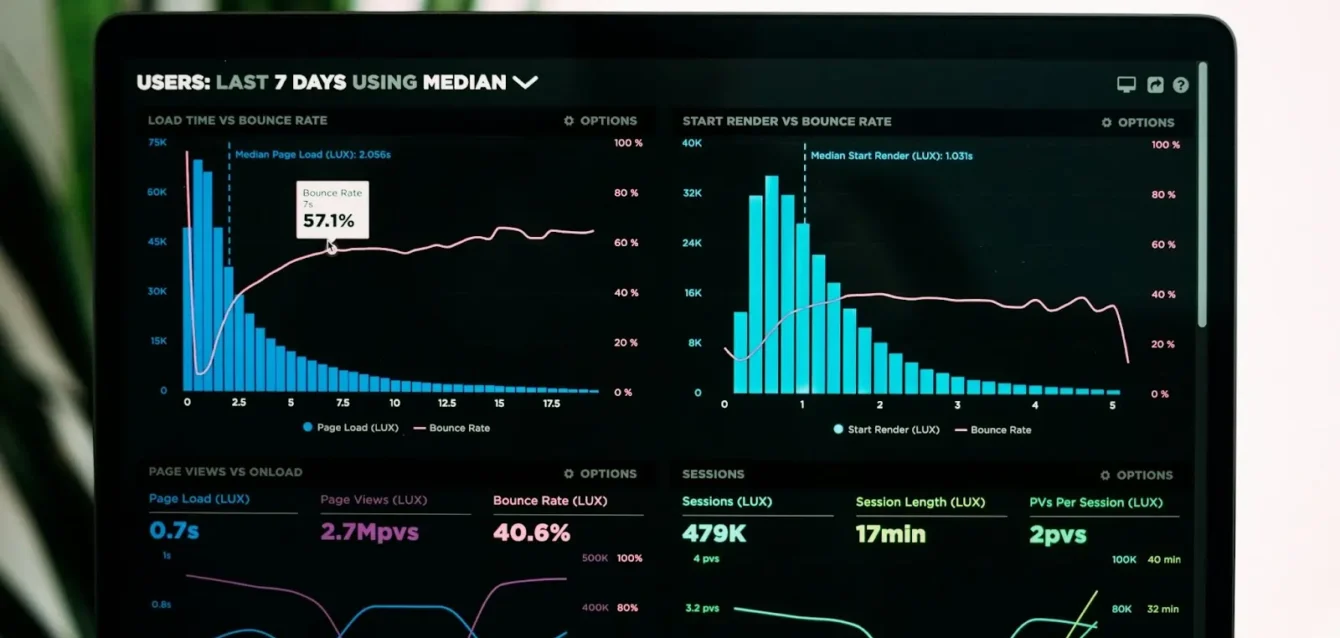

The image above shows predictive dashboards and how performance metrics and risk factors are visualized.

Strategic Benefits of Using AI in Asset Management

In addition to operational efficiency, the use of AI and IoT data gives organizations a competitive edge. Asset managers can evaluate future performance, measure investment risk, and optimize capital allocation in a data-driven environment.

This type of oversight affects long-term planning in the following ways:

- Better procurement choices thanks to lifecycle cost analysis

- Live condition driven adaptable maintenance scheduling

- Data driven strategies for upgrades and replacements

- Improved return on investment (ROI) calculations across asset portfolios

- Greater protection against fluctuations in the market

- Enhanced operational planning through the use of digital twin technology which provides a virtual representation of a company’s physical assets and enables them to simulate operational adjustments before making them in the real world

Security, Scalability, and Governance

To unlock the true potential of IoT data, organizations need to prioritize cybersecurity and governance frameworks as the connected assets increase digital attack surfaces.

An automated, intelligent, and responsive workflow for effective asset lifecycle management requires their assets to be protected with robust, scalable, and integrated security, digital rights management, lifecycle governance, and data protection compliance frameworks.

By prioritizing innovation and responsible governance, organizations can ensure long-term sustainability.

The Future of Intelligent Asset Lifecycles

The rapid advancement of technology in the field of asset lifecycle management has been remarkable. The advent of edge AI, autonomous maintenance robots, and sophisticated digital twins are expected to increase efficiency. As machine learning continues to evolve, predictive planning will become even less uncertain as predictive maintenance will be necessary.

Over the next several years, organizations will likely integrate AI-powered IoT analytics at every stage of the asset lifecycle, including acquisition, deployment, optimization, and retirement. Organizations that adopt this intelligent approach will extend the life of their assets and transform the way they conduct business.

Conclusion

AI-powered IoT analytics is transforming asset management. The infusion of intelligent analytics into continuous data collection provides the ability to ‘see’ the future, a capability previously unavailable to companies. AI combined with the IoT provides the ability to ‘see’ the future, a previously unavailable capability, through predictive asset management, predictive maintenance, and analytics, reduced downtime, IoT analytics, likely to predict more accurately, and enhanced data-driven values and integrated asset lifecycle management IoT.

In a rapidly evolving technological environment, the need for intelligent asset management is acute. Organizations that implement AI in asset management today will create operations that are more resilient, efficient, and prepared for the future.